Samsung Galaxy S8’s Manufacturing Cost Exceeds It’s Predecessors

The reason behind hike in price of Samsung Galaxy S8 in comparison to it’s predecessors is that it costs Samsung more money to make the Galaxy S8 than the S7. Companies always sell their products at higher prices to generate profit, and the prices include other factors such as marketing costs and taxes as well.

The difference between the production cost and the cheapest retail price of the Galaxy S8 — $720 — is exactly $412.5. However, this isn’t the amount of money Samsung makes every time it sells a unit of its flagship device. We also have to take the shipping and marketing expenses into account as well as various import fees in different countries. Additionally, retailers and carriers take their cut of every sale. There’s also the cost of research and development – Samsung has one of the highest R&D budgets in the industry – $13 billion in 2016 alone – and some of that money went into developing technologies like the iris scanner and edge display. Finally, a large administrative overhead (expenses and salaries of executives and managers) has to be taken into account.

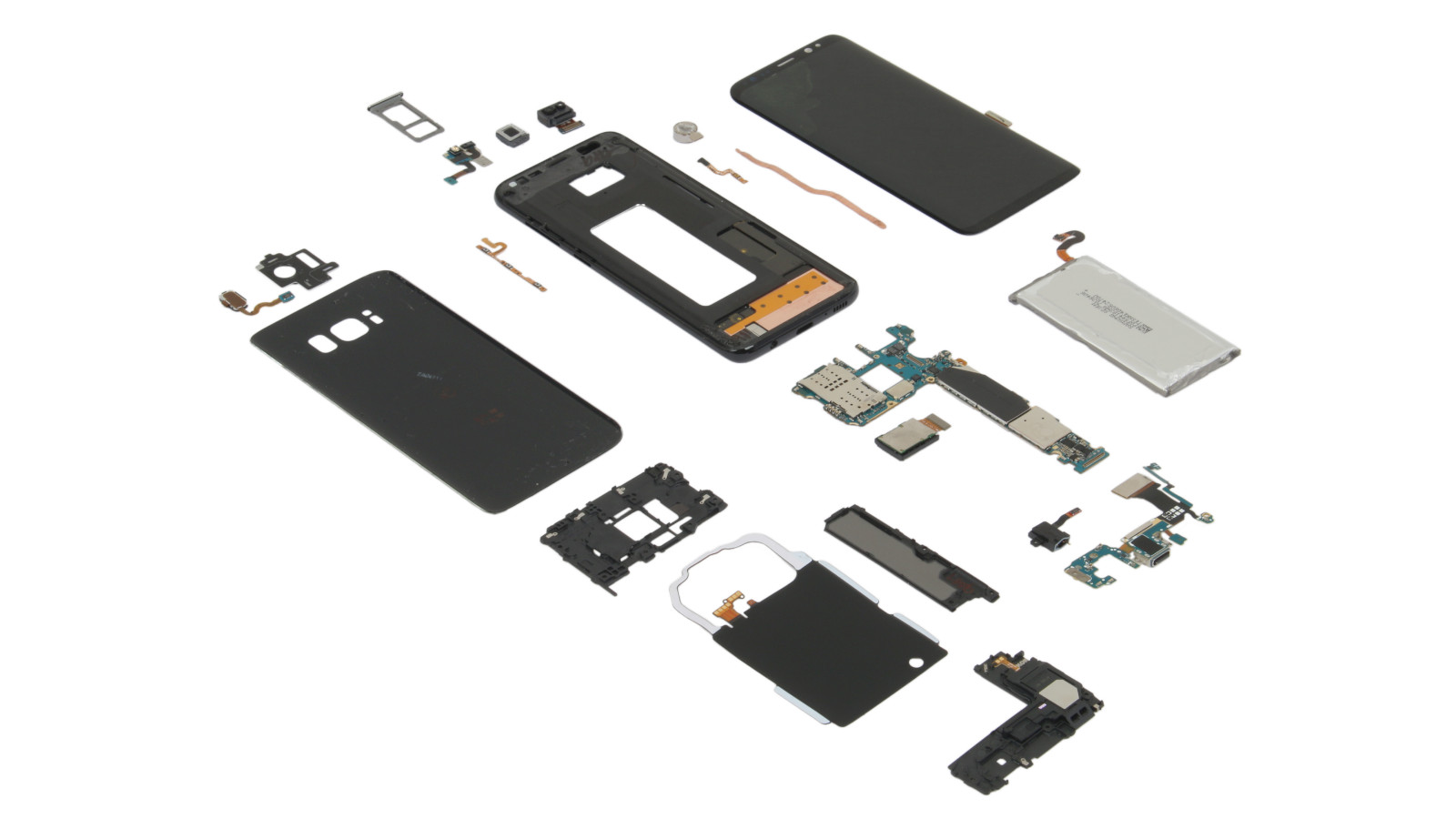

So how much profit Samsung stands to earn on each Galaxy S8 it sells? IHS Markit seems to have the answer. According to the report, the total bill of materials (BOM) for the 64GB storage variant of the Samsung Galaxy S8 comes out to be around $301.60 (roughly Rs 19,500). After adding the manufacturing cost of $5.9 (roughly Rs 381), the final amount comes to $307.50 (about Rs 19,900). It has been mentioned that this amount is $43.34 (roughly Rs 2,800) more than what it took Samsung to manufacture the Galaxy S7. The S7 edge was manufactured at $36.29 (roughly Rs 2,300) less.

IHS Markit has not detailed the component price of each device. However, it says that the NAND flash memory and DRAM cost $41.50 (roughly Rs 2,700) in total. The 3,000mAh battery costs $4.50 (roughly Rs 291).